JB Nordic has supplied the Nordic market with hundreds of machines over the past 10 years. With the right technology, our support and training, we have helped our customers increase their quality, control and, not least, their profitability. Together with our partner vhf, who has over 25 years of experience in manufacturing milling machines, milling tools and creating milling strategies, we know that our customers feel secure.

We are the largest in milling machines!

Profitability with efficient milling machines

Milling machines can make your work more efficient in many ways. Of course, in addition to becoming more profitable, it is also about gaining greater control over quality, materials and delivery times. Dental labs in the Nordic region now have a rare opportunity to become more efficient.

Milling in a variety of materials

We are the largest supplier in the Nordic region of dental milling materials. Over 100,000 joints are made in our materials annually, within the Nordic region.

We test the materials and make sure that you as a customer get the best. With us you can feel confident that you are getting really good quality at the right price.

Free consultation

Are you faced with a choice of equipment and consumables or need guidance on dental technology processes? We will help you and your lab.

Optimized and simple

Both machines and software are very user-friendly. The milling strategies for material and construction type are pre-programmed.

All the milling tools you need are already registered in the software. The milling strategies are optimized for material properties and tools. Updates are released regularly and new tools are added as needed.

Precision tools

Vhf original tools are characterized by high resistance to wear and can handle everything from wax to composites and CoCr.

Feel the precision!

Order a free sample

3D printing, efficient milling machines and digital workflows. Do you want to hold a bite splint or model in your hand, and get a feel for the results our technology can give you? Order a free sample from us.

All our machines from vhf

Ease Class

5

Axles

1

Blanks

16

Block

17

Tools

vhf E5

Dry milling | Affordable five-axis dry milling machine, easy to use and maintain. Low initial cost because no compressor required. The E5 is a flexible machine for wax, plastic, composite and zirconia. Well suited for a smaller lab or as a complement to other milling machines.

Advantages:

- No compressor needed

- CAM software included (DentalCAM)

- Takes 10 – 40 mm blanks

- 12 month warranty

Technical data:

- 5 axles

- 60.000 rpm/800 W

- Dimensions W/D/H 472/484/734 mm

- Weight 43 kg

4

Axles

0

Blanks

1

Block

7

Tools

vhf E4

Dry + wet milling | Affordable Chareside machine built for wet milling of blocks. Easy to use and maintain. Low initial cost because no compressor is required. Quick material changes that do not require tools. Built-in computer. E4 is a flexible machine for glass ceramics, plastic, wax, composite and zirconia blocks. Is for clinics or smaller labs or as a complement to other milling machines.

Advantages:

- No compressor needed

- Small and easy to place

- Built-in computer

- CAM software included (DentalCAM)

- 12 month warranty

Technical data:

- 4 axles

- 60.000 rpm/800 W

- Dimensions W/D/H 360/370/490 mm

- Weight 28kg

3+1

Axles

1

Aligner

1

Tools

vhf E3

Dry milling | User-friendly and easy to maintain. Low initial cost because no compressor required. E3 a fast machine for aligners and soft bite splints. Well suited for clinics.

Advantages:

- No compressor needed

- CAM software included (DentalCAM)

- Takes up to 3 blocks

- 12 month warranty

Technical data:

- 3+1 axles

- 60.000 rpm/800 W

- Dimensions W/D/H 360/370/490 mm

- Weight 25kg

Performance Class

5

Axles

8

Blanks

24

Block

16

Tools

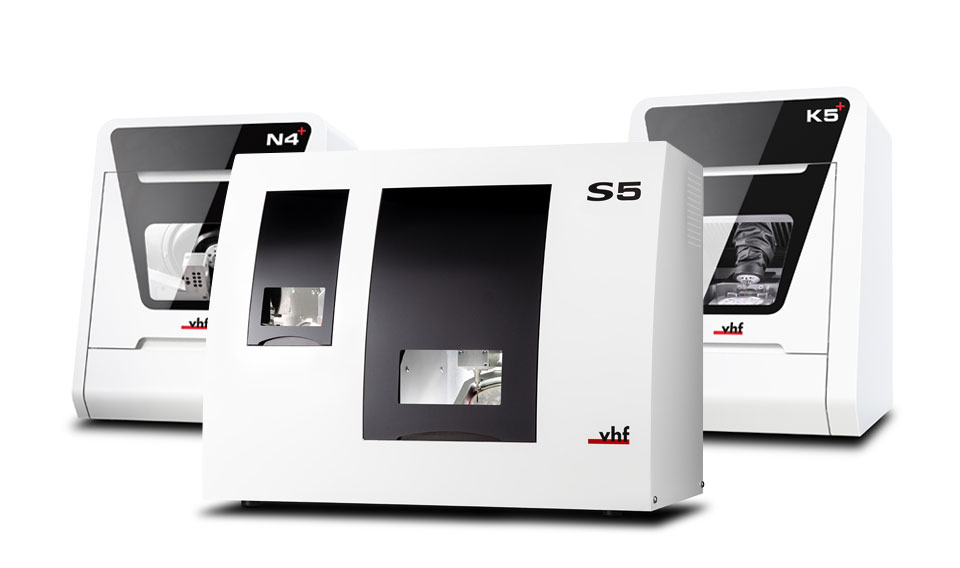

vhf S5

Dry + Wet Milling | A stable and well-proven workhorse. Made for high-volume dental labs that want to produce high quality, quickly and smoothly. It has five axes and a blank changer with space for 8 blanks. New blanks can be inserted during milling but the S5 is also automated for non-stop production e.g. overnight. Accommodates most materials including CoCr.

Advantages:

- Blank changer for 8 blanks

- Non-stop production

- CAM software included (DentalCAM)

- Takes 10 – 40 mm blanks

- Ionizers for cleaning

- 12 month warranty

Technical data:

- 5 axles

- 60.000 rpm/500 W

- Dimensions W/D/H 692/445/540 mm

- Weight 91 kg

5

Axles

1

Blanks

3

Block

16

Tools

vhf K5+

Dry milling | A stable, five-axis multi-talent that can do most things. Made for dental labs or clinics for those who want an affordable system that can handle most indications, in most materials on the market, e.g. CoCr.

Many comfort features, such as the screwless blank holder, so you can change materials super fast without the need for extra tools, which means you can work quickly and efficiently with the K5+

Advantages:

- Quick material change

- CAM software included (DentalCAM)

- Takes 10 – 40 mm blanks

- Ionizers for cleaning

- 12 month warranty

Technical data:

- 5 axles

- 60.000 rpm/820 W

- Dimensions W/D/H 450/545/630 mm

- Weight 91 kg

4

Axles

0

Blanks

3

Block

8

Tools

vhf N4+

Wet grinding | A versatile grinding machine made for dental labs that want an affordable system. The N4+ is a smooth grinding machine for glass ceramics, composites, zirconia blocks and titanium bases. With the N4+ you get a compact machine with built-in water cooling and space for 3 blocks.

Advantages:

- CAM software included (DentalCAM)

- Takes up to 3 blocks

- 12 month warranty

Technical data:

- 4 axles

- 80.000 rpm/800 W

- Dimensions W/D/H 360/450/470 mm

- Weight 53 kg

Hi End Class

5

Axles

10

Blanks

60

Block

16

Tools

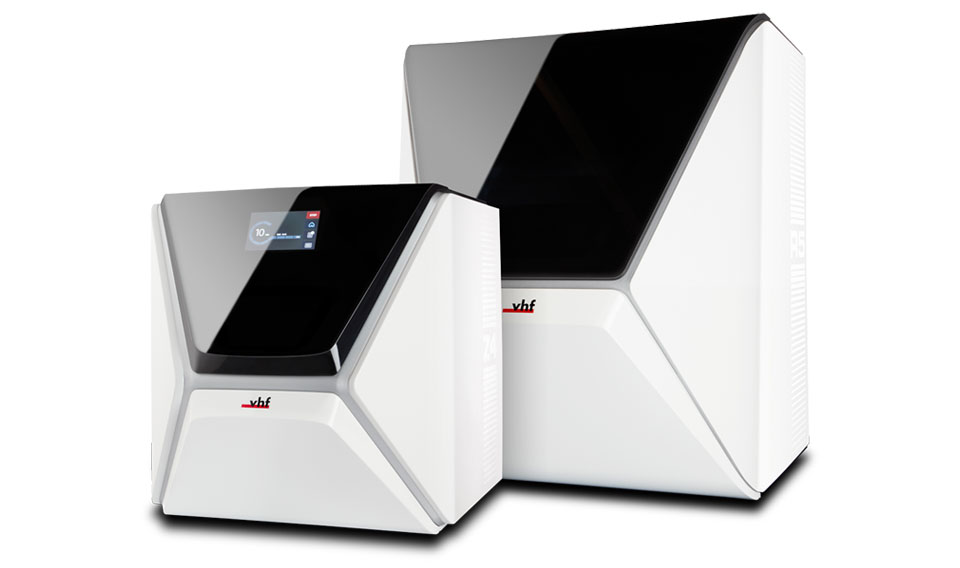

vhf R5

Dry + wet milling | A fast, automated milling and grinding machine for non-stop dry and wet processing e.g. overnight. The R5 has a blank changer for 10 blanks and is designed for dental labs with slightly higher volume production. Quick material changes that do not require tools. Handles most materials including CoCr.

Advantages:

- Blank changer for 10 blanks

- Non-stop production

- Quick material change

- CAM software included (DentalCAM)

- Takes 10 – 40 mm blanks

- Ionizers for cleaning

- 12 month warranty

Technical data:

- 5 axles

- 80.000 rpm/800 W

- Dimensions W/D/H 580/600/700 mm

- Weight 150 kg

4

Axles

0

Blanks

1

Block

6

Tools

vhf Z4

Wet milling | A very precise Chareside machine for quick jobs for clinics. Handles most materials including titanium (not CoCr).

Advantages:

- Fast, <10 min/block

- Precise (3 μm)

- Built-in computer

- CAM software included (DentalCAM)

- 12 month warranty

Technical data:

- 4 axles

- 100.000 rpm/340 W

- Dimensions W/D/H 471/522/507 mm

- Weight 66 kg

Recycle your CoCr!

We help you protect the environment.

Recycle your used CoCr blanks, regardless of brand or supplier, and get a discount code to use in our webshop. Simple environmental thinking!

How does it work?

- Download the form.

- Fill in your contact information and print the form.

- Pack your blanks together with the form and send them to us.

We weigh the material and email a discount code corresponding to the value of your CoCr. Everything is then sent by us for recycling.

Simple and safe!

Training

We get you started and assist with continuing education whenever you need it. A training plan is always drawn up together with you before the training starts.

Service

Our service technicians are authorized and know the machines we sell inside and out. This allows us to troubleshoot and fix problems quickly.